Product Details;

CasNo: 79-14-1

Molecular Formula: C2H4O3

Appearance: Light yellow to amber liquid

79-14-1 Properties

- Molecular Formula:C2H4O3

- Molecular Weight:76.052

- Appearance/Colour:Light yellow to amber liquid

- Vapor Pressure:0.001mmHg at 25°C

- Melting Point:75-80 °C(lit.)

- Refractive Index:n20/D 1.424

- Boiling Point:265.6 °C at 760 mmHg

- Flash Point:128.7 °C

- PSA:57.53000

- Density:1.416 g/cm3

- LogP:-0.93670

79-14-1 Usage

InChI:InChI=1/C2H4O3/c3-1-2(4)5/h3H,1H2,(H,4,5)/p-1

79-14-1 Relevant articles

Gas Evolution Oscillators. 2. A Reexamination of Formic Acid Dehydration

Smith, Kenneth W.,Noyes, Richard M.,Bowers, Peter G.

, p. 1514 - 1519 (1983)

At formic acid concentrations of about 0.3 M in warm concentrated sulfuric acid, carbon monoxide is evolved smoothly whether the solution is stirred or not.If such a solution is rapidly stirred, decay of formic acid obeys clean irreversible first-order kinetics.If the solution is not stirred, the concentration of dissolved carbon monoxide rises to a limit of about 0.07 M; this value is about 80 times the equilibrium solubility at 1 atm.In an unstirred solution, the system approaches a "pseudoequilibrium" in which the concentrations of dissolved HCOOH and CO are about equal.If the concentration of formic acid is increased to about 4 M, gas is evolved from a gently stirred solution in oscillatory pulses.The amount of gas evolved during a pulse decreases with successive pulses, the maximum change in dissolved-gas concentration being approximately 0.07 M per pulse.These observations indicate that the oscillations result from repetitive release of supersaturation by homogeneous nucleation; they invalidate the purely chemical explanation developed by Showalter and Noyes.Supersaturations of up to 80-fold suggest that formic acid in concentrated sulfuric acid can generate carbon monoxide in situ at concentrations that could otherwise only be attained with high-pressure apparatus.

Glycolic acid production using ethylene glycol-oxidizing microorganisms

Kataoka, Michihiko,Sasaki, Mie,Hidalgo, Aklani-Rose G.D.,Nakano, Michiko,Shimizu, Sakayu

, p. 2265 - 2270 (2001)

Screening for microorganisms oxidizing ethylene glycol to glycolic acid was carried out. Among stock cultures, several yeasts and acetic acid bacteria showed high glycolic acid producing activity. Pichia naganishii AKU 4267 formed the highest concentration of glycolic acid, 35.3 g/l, from 10% (v/v) ethylene glycol (molar conversion yield, 26.0%). Among soil isolates, Rhodotorula sp. 3Pr-126, isolated using propylene glycol as a sole carbon source, formed the highest concentration of glycolic acid, 25.1 g/l, from 10% (v/v) ethylene glycol (molar conversion yield, 18.5%). Rhodotorula sp. 3Pr-126 showed higher activity toward 20% (v/v) ethylene glycol than P. naganishii AKU 4267. Optimization of the conditions for glycolic acid production was investigated using P. naganishii AKU 4267 and Rhodotorula sp. 3Pr-126. Under the optimized conditions, P. naganishii AKU 4267 and Rhodotorula sp. 3Pr-126 formed 105 and 110 g/l of glycolic acid (corrected molar conversion yields, 88.0 and 92.2%) during 120 h of reaction, respectively.

Glycolic acid formation in Chlorella.

WARBURG,KRIPPAHL

, (1960)

-

Theoretical study of Al(iii)-catalyzed conversion of glyoxal to glycolic acid: Dual activated 1,2-hydride shift mechanism by protonated Al(OH) 3 species

Ohshima, Takashi,Yamamoto, Yoshihiro,Takaki, Usaji,Inoue, Yoshihisa,Saeki, Takuya,Itou, Kenji,Maegawa, Yusuke,Iwasaki, Takanori,Mashima, Kazushi

, p. 2688 - 2690 (2009)

Density functional theory calculations demonstrate that Al(iii)-catalyzed conversion of glyoxal to glycolic acid proceeds via a 7-membered dual Lewis acid-hydrogen bonding activation transition state of the 1,2-hydride shift, rather than the previously proposed 5-membered metal-alkoxide chelate activation transition state. The Royal Society of Chemistry 2009.

Facilitated series electrochemical hydrogenation of oxalic acid to glycolic acid using TiO2 nanotubes

Im, Sunmi,Park, Yiseul,Saad, Sarwar

, (2022/01/11)

In this study, the electrochemical reduction of oxalic acid (OX) was performed at electrodes made of TiO2 nanotubes (TNTs) in an aqueous medium under potentiostatic control in a two-compartment cell. The competing H2 evolution was almost non-existent at an applied potential of ?1.0 V vs Ag/AgCl. Thus, complete conversion of OX was achieved in high chemical (95%) and Faradaic (67%) yields. The selectivity of glycolic acid (GC) formation over that of glyoxylic acid (GO) is controlled by the length of the TNTs. A high selectivity (GC/GO ≈ 10) was obtained (glycolic acid/glyoxylic acid ≈ 10). The physical properties of the TNTs, such as length, uniformity, and mechanical strength, were controlled by varying the anodization time and the electrolyte composition.

Oxidative Conversion of Glucose to Formic Acid as a Renewable Hydrogen Source Using an Abundant Solid Base Catalyst

Takagaki, Atsushi,Obata, Wataru,Ishihara, Tatsumi

, p. 954 - 959 (2021/07/14)

Formic acid is one of the most desirable liquid hydrogen carriers. The selective production of formic acid from monosaccharides in water under mild reaction conditions using solid catalysts was investigated. Calcium oxide, an abundant solid base catalyst available from seashell or limestone by thermal decomposition, was found to be the most active of the simple oxides tested, with formic acid yields of 50 % and 66 % from glucose and xylose, respectively, in 1.4 % H2O2 aqueous solution at 343 K for 30 min. The main reaction pathway is a sequential formation of formic acid from glucose by C?C bond cleavage involving aldehyde groups in the acyclic form. The reaction also involves base-catalyzed aldose-ketose isomerization and retroaldol reaction, resulting in the formation of fructose and trioses including glyceraldehyde and dihydroxyacetone. These intermediates were further decomposed into formic acid or glycolic acid. The catalytic activity remained unchanged for further reuse by a simple post-calcination.

The selective oxidation of glycerol over metal-free photocatalysts: insights into the solvent effect on catalytic efficiency and product distribution

Fan, Mingming,Haryonob, Agus,Jiang, Pingping,Leng, Yan,Yue, Chengguang,Zhang, Pingbo

, p. 3385 - 3392 (2021/06/06)

Selective oxidation of glycerol to high value-added derivatives is a promising biomass conversion pathway, but the related reaction mechanism, in particular the solvent effect, is rarely studied. In this work, O-doped g-C3N4was used as a metal-free catalyst to catalyze the selective oxidation of glycerol in different solvents. It was found that solvents can affect both catalytic efficiency and product distribution. A series of controlled experiments and theoretical calculation were applied to attest that the difference in interaction between glycerol and catalysts in different solvents is the main factor: competitive adsorption and hydrogen bond network from water inhibit the adsorption and activation of glycerol on the catalyst surface and reduce the conversion efficiency, while in acetonitrile, the stronger adsorption makes the oxidation reaction continue to yield esters. Two reaction routes in different solvents over O-doped g-C3N4are proposed for the first time, which is helpful for people to better understand the related reaction mechanism.

Electro-oxidation of glycerol into formic acid by nickel-copper electrocatalysts

Shen, Yi,Zhang, Jiali

, (2021/09/11)

Herein, non-precious metallic nickel-copper electrocatalysts were synthesized for electro-oxidation of glycerol in alkaline electrolytes. Activated carbon felt (ACF) is used as a supporting material because of its good conductivity, chemical inertness, and porous structure which is conducive to the transport of the reactants/electrons. The structural features of the catalysts were characterized by scanning electron microscopy, X-ray diffraction and X-ray photoelectron spectroscopy. The electrochemical activity of the catalysts was revealed by cyclic voltammetry, linear sweeping voltammetry, and chronoamperometry. The electrochemical results show that the Cu1Ni1@ACF catalyst possesses the highest current density of 1.31 mA cm-2 at 1.895 V. High-performance liquid chromatography results show that the as-prepared catalysts have high selectivities for formic acid (FA). Especially, the Cu1Ni1@ACF catalyst yields a selectivity of 97.4% for FA, which has so far been the largest value reported in the literature. Additionally, the effects of applied potentials and reaction time on product selectivity were studied.

79-14-1 Process route

-

- 87-69-4,138508-61-9

L-Tartaric acid

-

- 124-38-9,18923-20-1

carbon dioxide

-

- 7664-93-9

sulfuric acid

-

- 79-14-1

glycolic Acid

-

- 133-37-9,138508-61-9

DL-tartaric acid

-

- 127-17-3

2-oxo-propionic acid

| Conditions | Yield |

|---|---|

|

|

-

- 81-88-9

rhodamine B

-

- 103-82-2

phenylacetic acid

-

- 79-14-1

glycolic Acid

-

- 849585-22-4,106989-11-1,26811-96-1,31587-11-8,26100-51-6

LACTIC ACID

-

- 57-55-6,63625-56-9

propylene glycol

-

- 4065-81-0

cyclohexen-1-ol

-

- 18826-95-4,107-88-0

1.3-butanediol

-

- 626-89-1

4-Methyl-1-pentanol

-

- 100-21-0

terephthalic acid

-

- 84-74-2

Phthalic acid dibutyl ester

-

- 90-27-7

2-Phenylbutyric acid

-

- 108-93-0

cyclohexanol

| Conditions | Yield |

|---|---|

|

for 0.5h; pH=5; UV-irradiation; Darkness;

|

79-14-1 Upstream products

-

56-23-5

tetrachloromethane

-

53834-50-7

(Z)-1,2-dichloro-3-phenyl-2-propene

-

502-97-6

glycolide

-

50-00-0

formaldehyd

79-14-1 Downstream products

-

6478-80-4

5,6-dichloro-2-hydroxymethyl-1H-benzimidazole

-

87-51-4

indole-3-acetic acid

-

90357-58-7

n-propyl 2-hydroxyacetate

-

624-55-5

glycolic acid-(2-ethoxy-ethyl ester)

Relevant Products

-

4-Hydroxyphenethyl alcoholCAS NO.: 501-94-0

CAS:501-94-0

-

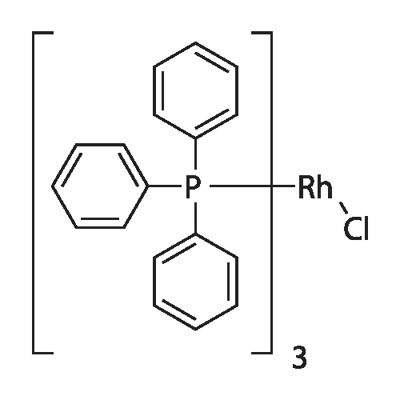

Rhodium,chlorotris(triphenylphosphine)-, (SP-4-2)-

CAS:14694-95-2

-

Salicylic acid

CAS:69-72-7